Elmer Francisco

Latest News

Landmark Agreement with Francisco Motors to Electrify Jeepneys in the Philippines

Jeepneys are iconic public utility vehicles in the Philippines, representing 40% of public transport Total addressable market estimated at US$10bn+ (excluding charging and other ancillary solutions) Established in 1947, Francisco Motors is the original pioneering jeepney manufacturer Francisco Motors and Tembo are already working towards delivering on committed orders Deal will benefit Tembo’s customer and partners in other industries including

eFrancisco Motor Corporation ONER

Introducing my son, Dominic Francisco’s, special project… Francisco ONER O – Okey N – Na E – Electric R – Ride Suggest your own acronym for the all new electric Francisco ONER! Dictionary meaning: ONER – an outstanding thing! Magkakaroon po ng iba’t ibang version nito tulad ng standard, lowered, lifted, 4×4, long wheelbase, short

eFrancisco Motor Corporation E-PINOY Class 1 PUV

eFrancisco Motor Corporation “E-PINOY” Class 1 PUV… Pwede po ba? Concept design by Royd. A work in progress. For prototyping. A modernized classic. Full electric. Gawang Pinoy! #DOTrPH #eFMC #Francisco #eFranciscoMotorCorporation #Pinoy #ePinoy #electric #ev #electricvehicle

eFrancisco Motor Corporation with Unionbank, Aboitiz Group, Arowana Impact Capital and ADERA Global

Kasama po ng eFrancisco Motor Corporation ngayong araw ang mga kinatawan ng Unionbank, Aboitiz Group, Arowana Impact Capital at ADERA Global: Mr. Anton Corro – Unionbank Asset-Backed Lending Head & Aboitiz Chief Cross Selling Officer, Mr. Jujut Enriquez – Unionbank Small and Medium Enterprise Banking Head, Ms. Cathy Casas – Unionbank Senior Vice President and

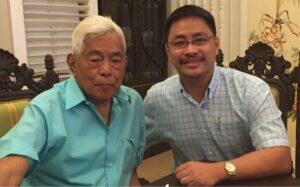

WORDS OF WISDOM FROM FORMER SENATE PRESIDENT NENE PIMENTEL

It is really true that a wise man must seek advice from someone who has already been where he is going and not from someone who never even had the courage to try. Thank you so much Former Senate President, Tatay Nene Pimentel, for the words of wisdom. Looking forward for more… …at The Laurel